METSA INDUSTRIAL - BUSINESS SOLUTIONS FOR YOUR COMPANY

ROTOR TECHNOLOGY - MAIN CHARACTERISTICS OF THE MANUFACTURING PROCESS

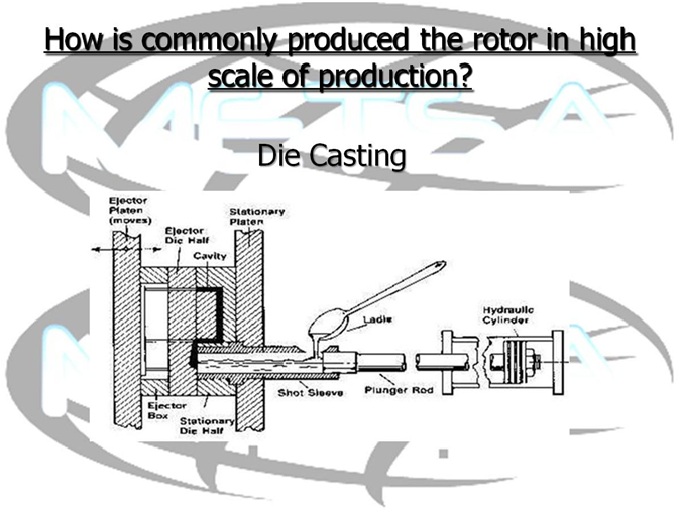

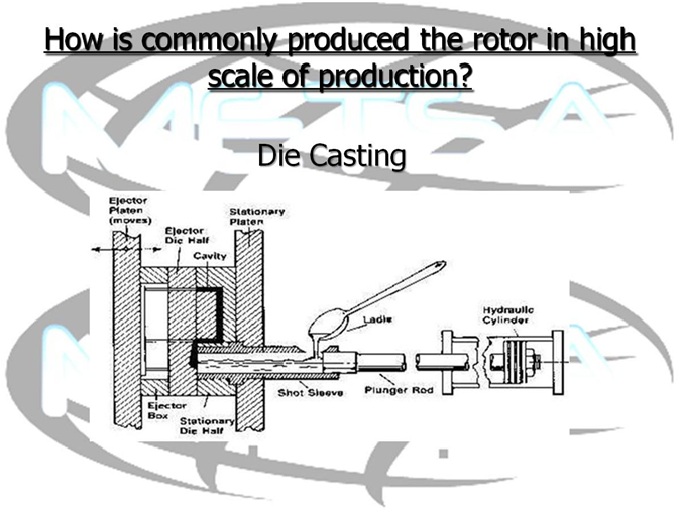

The rotor is usually produced by die-casting process.

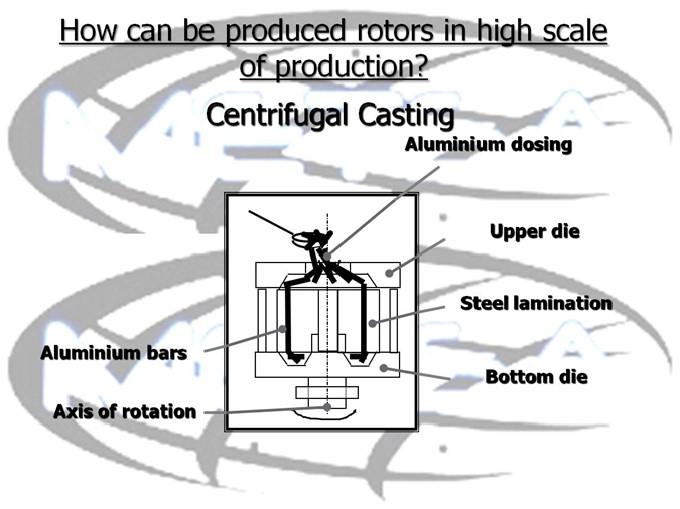

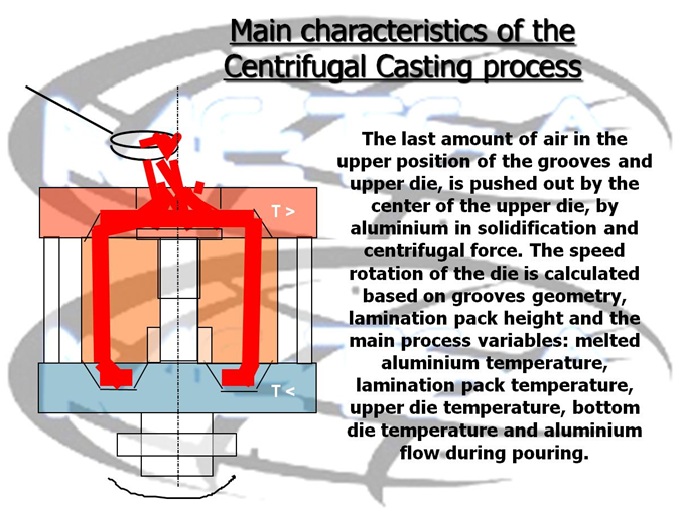

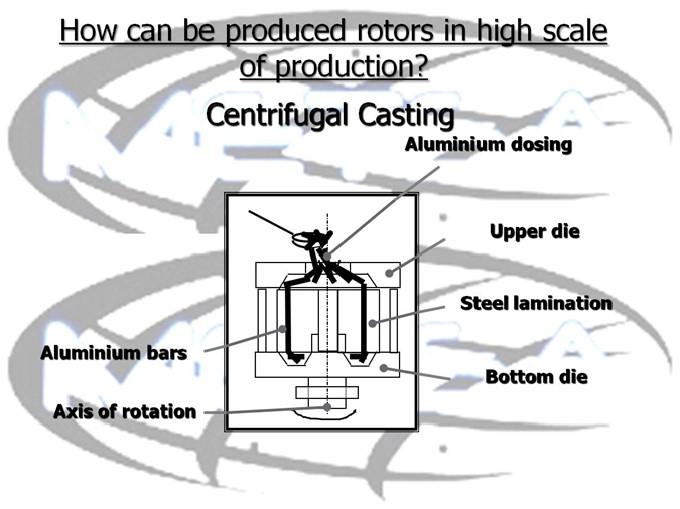

The rotor can also be produced by centrifugal casting.

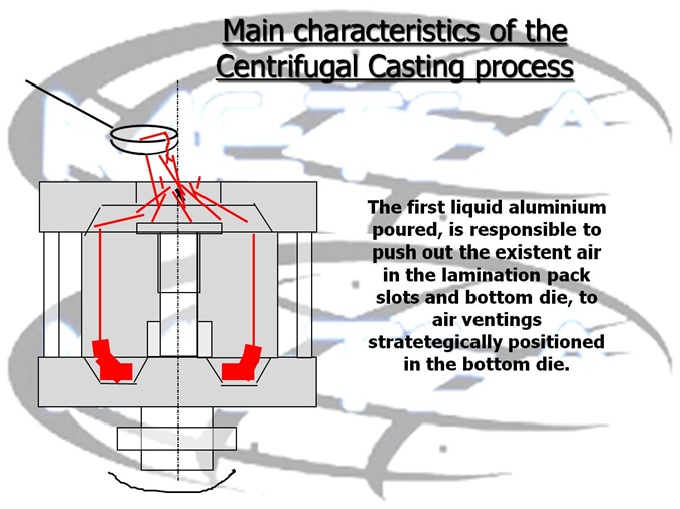

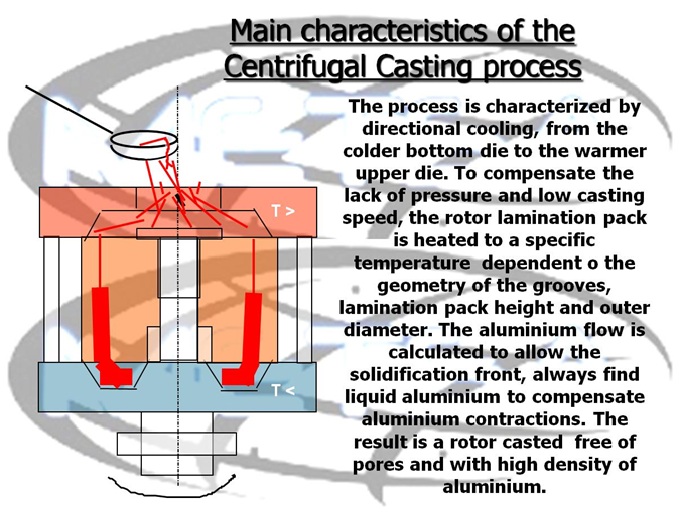

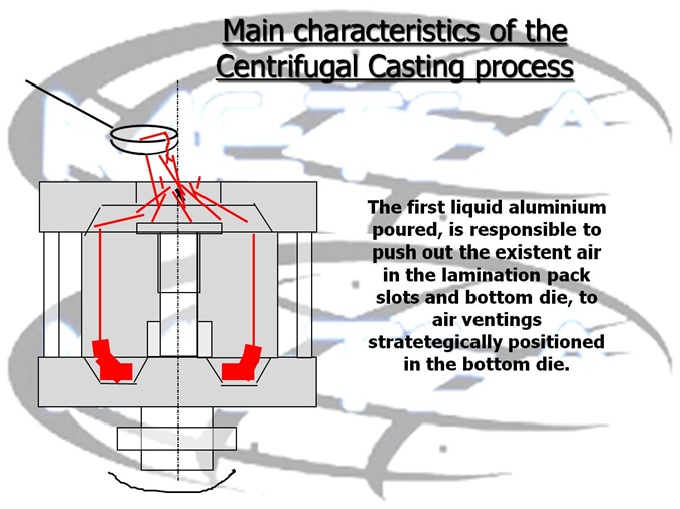

Beginning of the aluminium dosing.

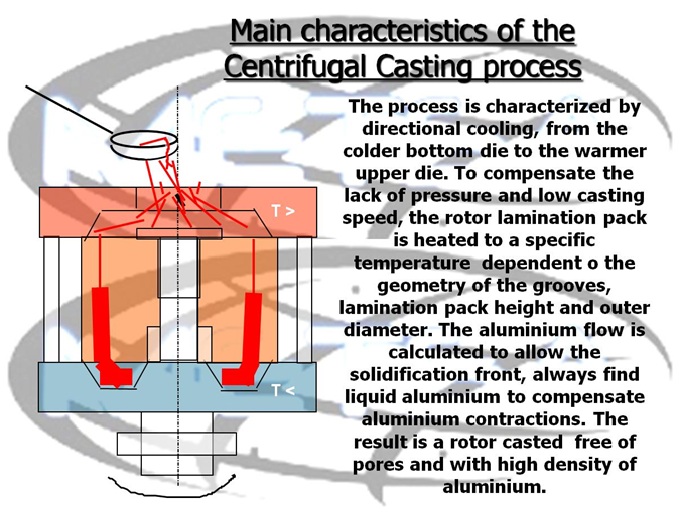

Half of the aluminium dosing.

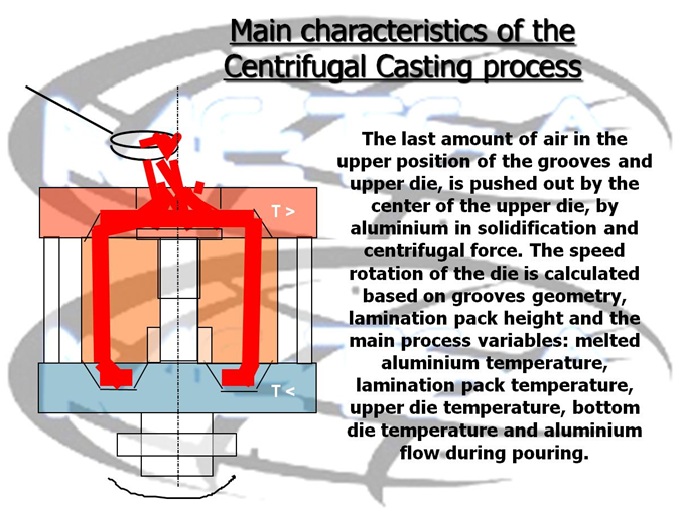

End of the aluminium dosing.

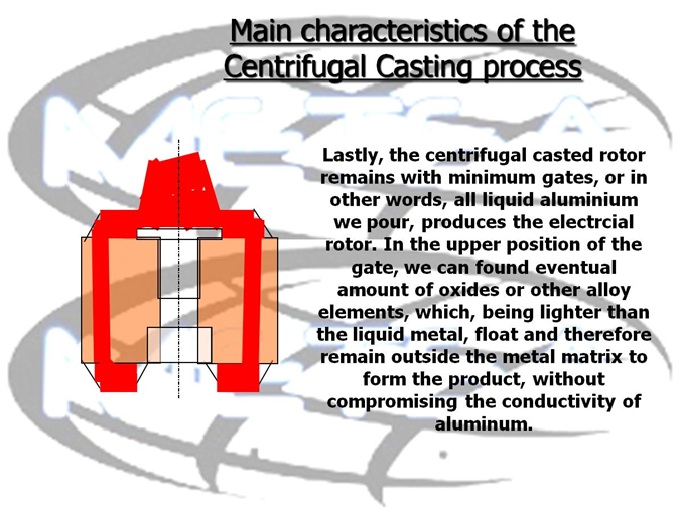

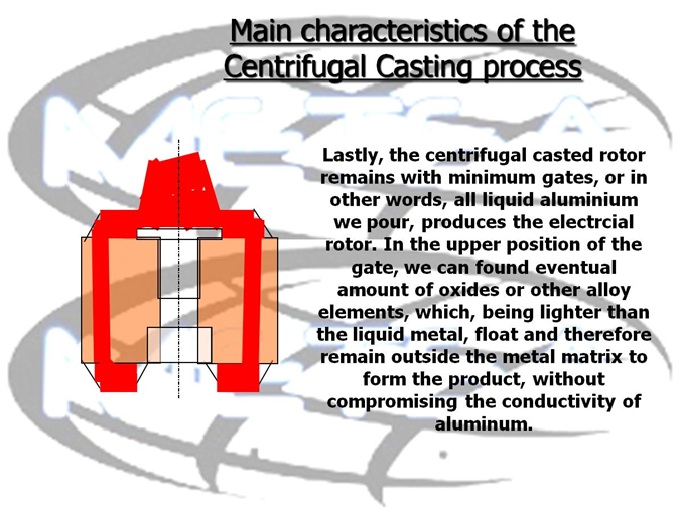

Semi-finished centrifugal casted rotor.

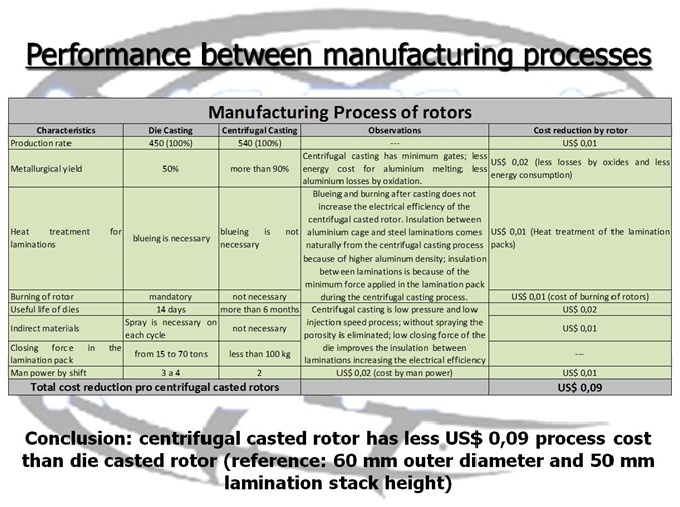

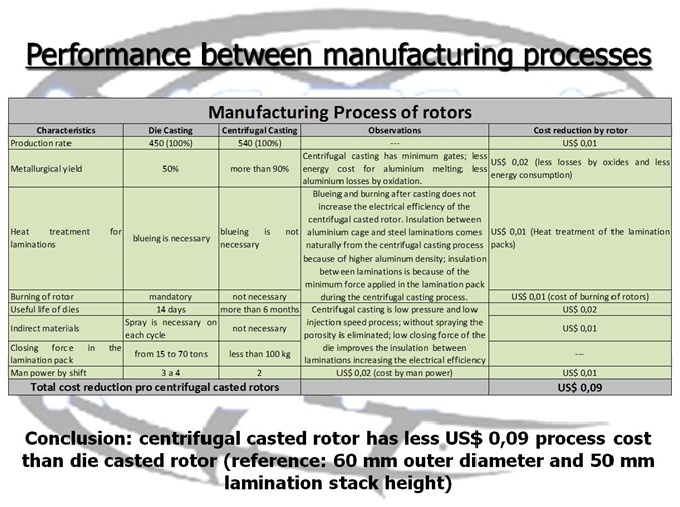

Comparative in the performance of the manufacturing processes of the rotor (centrifugal caste X die casted).

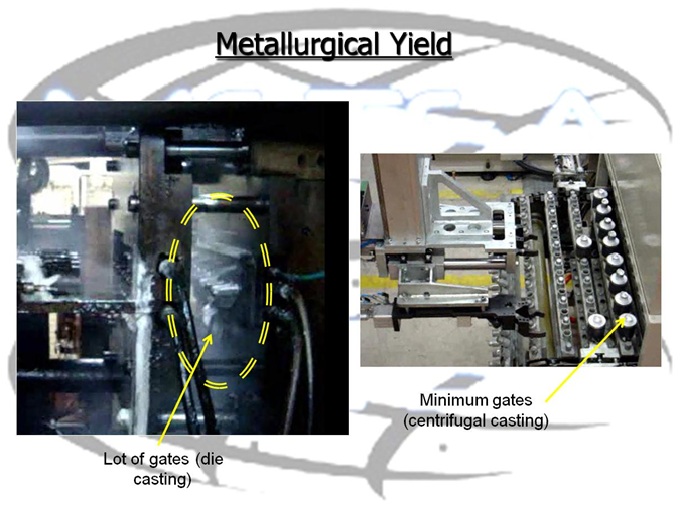

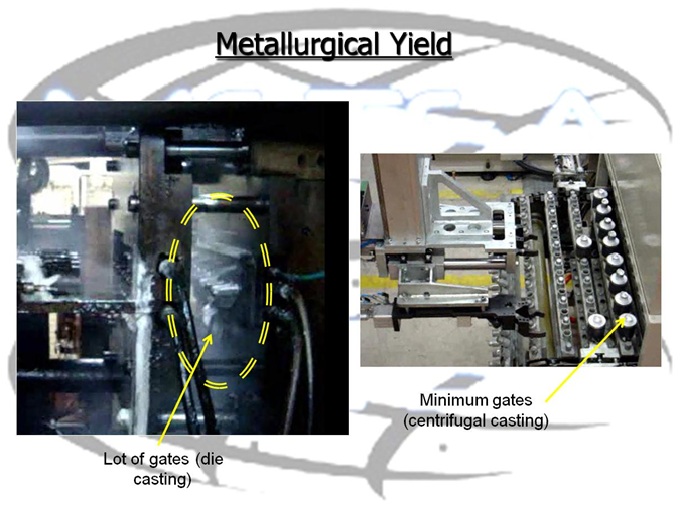

Comparative in the metallurgical yield of rotors produced by die casting and centrifugal casting process.

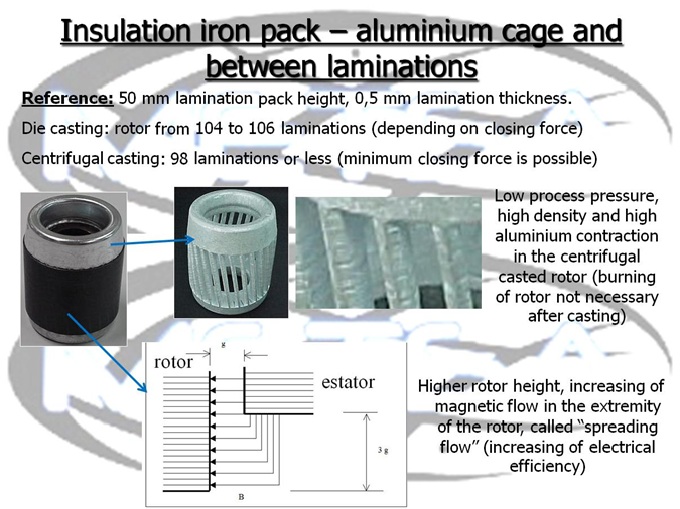

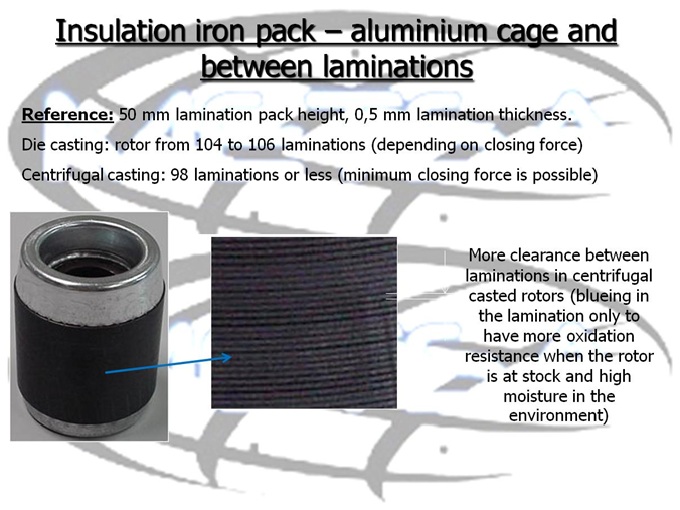

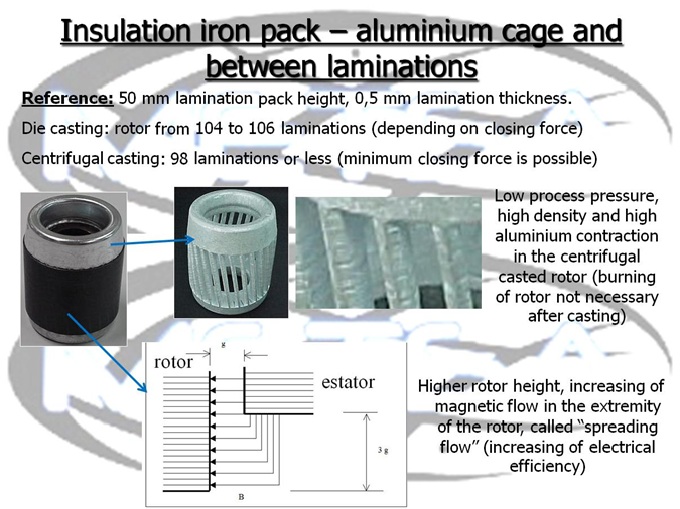

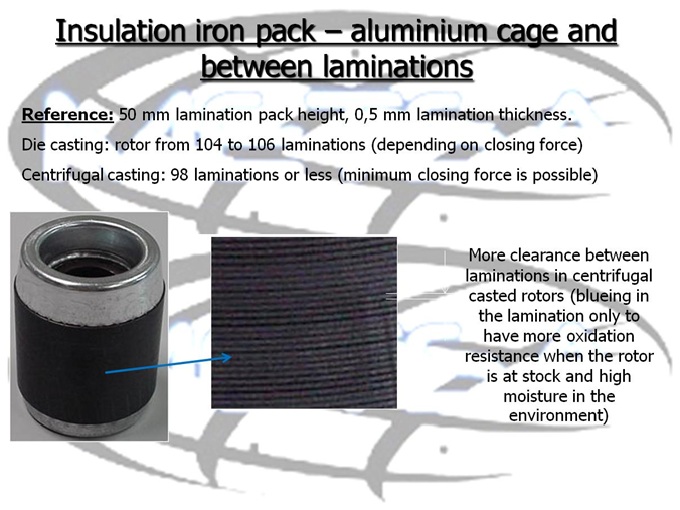

The centrifugal casting process promotes insulation between aluminum cage and steel lamination pack naturally by the process. The result is higher electrical efficiency of the rotor.

The centrifugal casting process promotes insulation between laminations naturally by the process. The result is higher electrical efficiency of the rotor.

For the centrifugal casting process it is not necessary the use of indirect materials as demolding, oils and greases. The process is cleaner and more economic.