METSA INDUSTRIAL - BUSINESS SOLUTIONS FOR YOUR COMPANY

INDUSTRIAL OVENS FOR METALS HEAT TREATMENT PRAFI - KNOW-HOW E.P. HUMBERT

We represent the company P.R.A.F.I. Srl, that have assumed all of the "Know-How" from Humbert company in 1996, including files of technical equipment and components, provided to the market the full line of products Humbert (the oldest and most renowned Italian company for systems and equipment for heat treatment, which operated in Italy since 1920). In the production unit, the P.R.A.F.I. srl, completed his staff with technicians who have over 25 years experience in Humbert.

All the files from Humbert were organized, even already extended by the productive activities of PRAFI Srl.

A P.R.A.F.I. Srl is located in Avigliana, Turin, Italy.

The P.R.A.F.I. Srl was equipped with machinery, apparatus and instrumentation required for the construction and assembly of the product itself. In that plant, is still pre-tested all the new equipment, with the participation of the client. The constant and deliberate commitment of PRAFI Srl, to customer service, part of the design phase of the project and lasts until the long-term maintenance in all aspects of its activity.

The P.R.A.F.I. Srl has in Avigliana, Turin, 1500 m² of constructed area, with a ceiling height of 8 meters and has 15 employees hired exclusively for electrical, software, mechanics, structure, insulation and heating design. We use the partner system technique for carrying out the work with assistance, monitoring and accountability of designers from PRAFI. This mode of operation allows for PRAFI competitiveness in the Italian market and internationally.

In the applications of heat treatment with radiant tubes (requiring protective atmosphere), they are centrifuged and made of stainless steel 310, resistant to 900 ° C and oxidation. The stainless steel 304 resists only to 600 ° C and has moderate resistance to oxidation and stainless 316 is extremely expensive, resistant to 650 ° C and oxidation. Steel 310 is the material most cost-effective for heating applications in protective atmosphere.

We use gas systems from Krom Schroeder and insulating materials provided by Johns Manville, the world's largest manufacturer of refractory insulation. We had the opportunity to provide heat treatment furnace for aluminum alloy for Alenia, a manufacturer of Italian fighter planes, with accurate treatment temperature of puls or minus 2 °C.

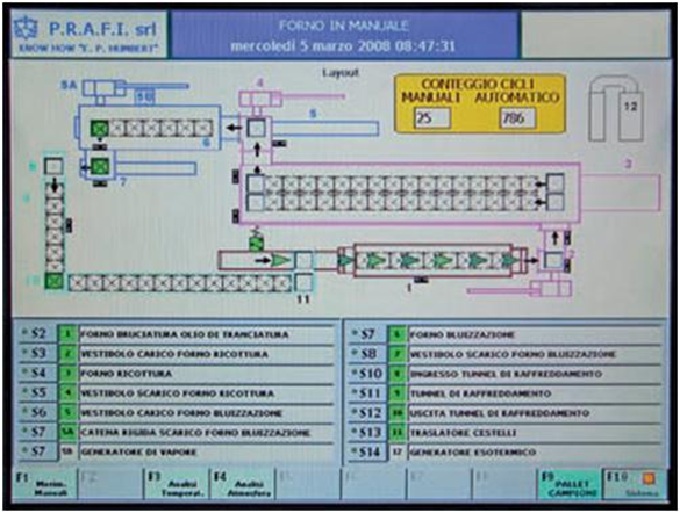

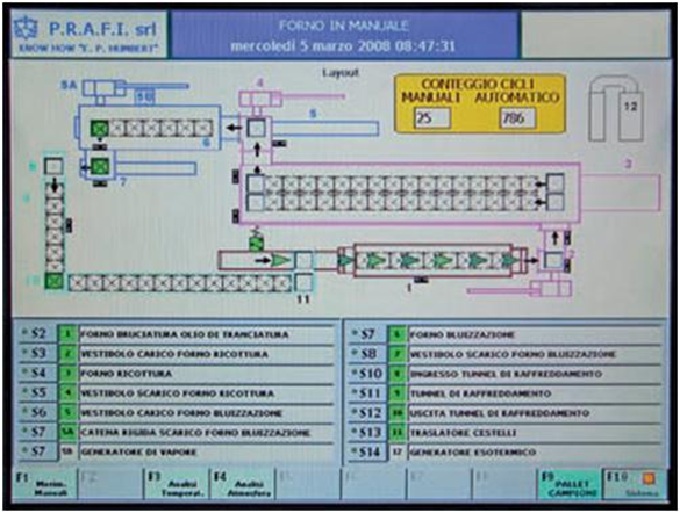

We develop software for System Management and Control of the whole atmosphere inside the furnace.