METSA INDUSTRIAL - BUSINESS SOLUTIONS FOR YOUR COMPANY

MELTING OVENS TYPE

Melting and holding furnaces dry hearth (dry soil). This oven is constructed with steel reinforced structural material Fe 37, built to meet all expectations of even the most demanding customers. They are built with the latest world refractories technologies, sized to provide excellent thermal insulation in external walls of the oven. Two termocouples allows temperature control of the liquid metal and the refractory walls of the oven. The exhaust system, fully automatic, has a recovering of combustion heat. Combustion systems of new generation burners Krom-SCHROEDER, with two potentiality of minimum and maximum to avoid peaks in bath temperature due to thermal inertia. Retention capabilities of aluminum: 300, 500, 800, 1,500 and 2,000 kg. Capacities of 150, 180, 200, 250, 300 and 350 kg per hour. The last one with 2 burners.

It feeds the ingot in the doorway, not in the aluminum bath, avoiding the risks of feeding ingots with moisture. Furthermore, due to the high retention capacity of aluminum, no change in bath temperature and does not need to stop production for load aluminum ingots.

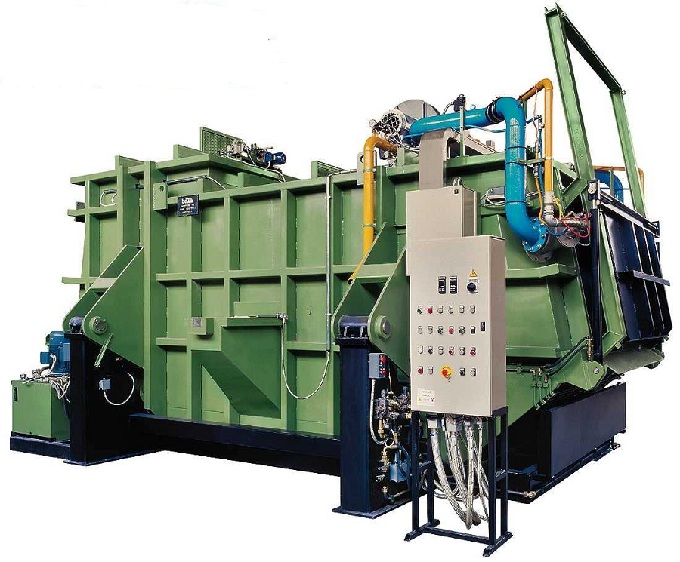

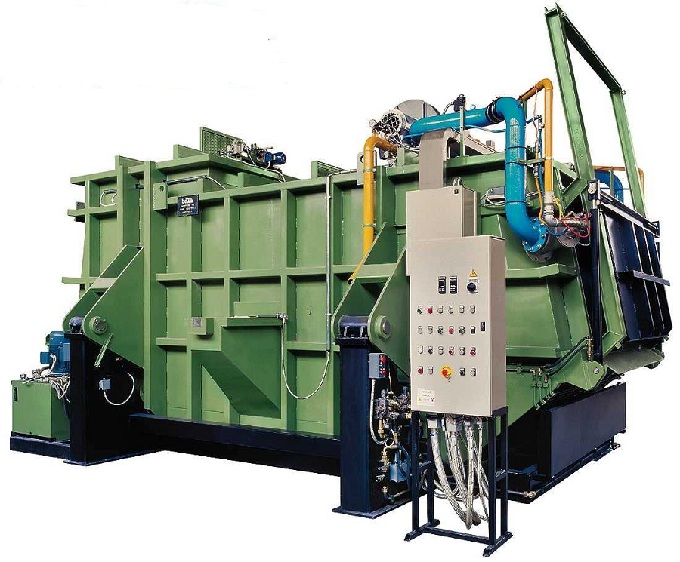

Tilting melting furnaces sill dry. Capacities from 5,000 to 25,000 kg. Melting capacities from 700 to 2,400 kg/h. Heated by natural gas, LPG or diesel. Combustion and temperature control in fully automatic. Automatic opening and closing of the exhaust system. Combustion systems of new generation burners Krom-SCHROEDER, with two potentiality of minimum and maximum to avoid peaks in the bath temperature due to thermal inertia.

Melting furnaces tower tilting sill dry. System for automatic loading of ingots. Retention Capacity aluminum from 1500 to 2700 kg. Melting capacities from 600 to 1,200 kg/h. Heated by natural gas, LPG or diesel. Combustion and temperature control in fully automatic. Automatic opening and closing of the exhaust system. With this type of furnace, the gas consumption can be 55 normal cubic meters per hour for melting 1,000 kg of aluminum or alloy. Combustion systems of new generation burners SCHROEDER-Krom. We guarantee customized solutions, high quality liquid metal, low power, low-loss of aluminum by oxidation and long life of the refractory.

Tilting or fixed melting furnaces, sill dry-feed with side chamber. System for automatic loading of ingots. Retention Capacity of aluminum from 1,500 to 10,000 kg. Melting capacities from 600 to 2,000 kg/h. Heated by natural gas, LPG or diesel. Combustion and temperature control in fully automatic. Automatic opening and closing of the exhaust system. With this type of furnace, the gas consumption can be 55 normal cubic meters per hour for melting 1,000 kg of aluminum or alloy. Combustion systems of new generation burners SCHROEDER-Krom. We guarantee customized solutions, high quality liquid metal, low power, low-loss of aluminum by oxidation and long life of the refractory.

Tilting or fixed melting furnaces, sill dry, with two towers for aluminum loading. System for automatic loading of ingots. Retention Capacity of aluminum from 4,000 to 20,000 kg. Melting capacities from 3,000 to 4,000 kg/h. Heated by natural gas, LPG or diesel. Combustion and temperature control in fully automatic. Automatic opening and closing of the exhaust system. With this type of furnace, the gas consumption can be 55 normal cubic meters per hour for melting 1,000 kg of aluminum or alloy. Combustion systems of new generation burners SCHROEDER-Krom. We guarantee customized solutions, high quality liquid metal, low power, low-loss of aluminum by oxidation and long life of the refractory.

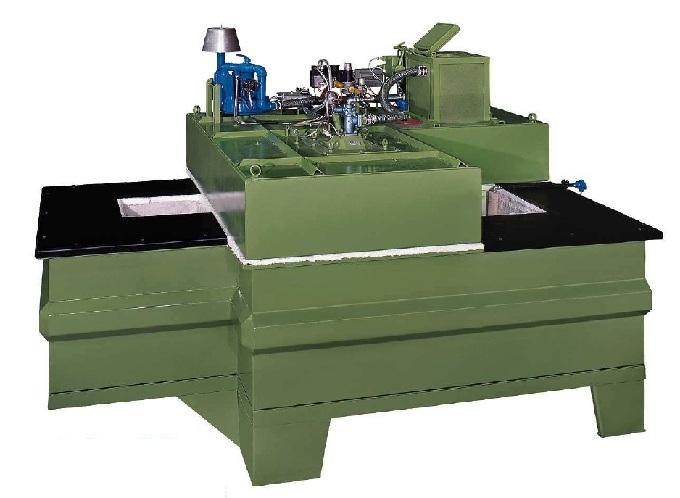

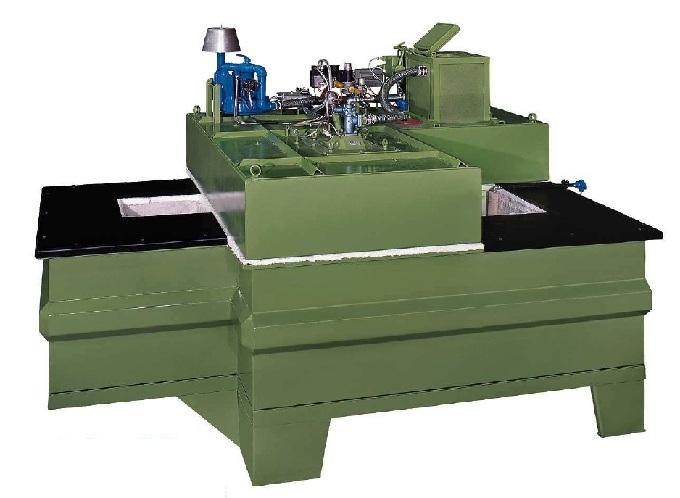

Holding furnaces, with one or two feeding bowls. Retention Capacity of aluminum from 1,200 to 3,000 kg. Heated by natural gas, LPG or diesel. Fully automatic temperature control. Automatic opening and closing of the exhaust system with heat recovery. Heating systems with new generation burners Krom-SCHROEDER. We guarantee customized solutions, high quality liquid metal, low power, low-loss of aluminum by oxidation and long life of the refractory.